How will new technologies in industrial design shape production in 2025?

In recent years, industrial design has been developing at a breathtaking pace and 2025 will be no exception. With the automation of systems, processes of design and production are accelerating and becoming more accurate and more environmentally friendly. Which technologies are shaping the future of industrial design?

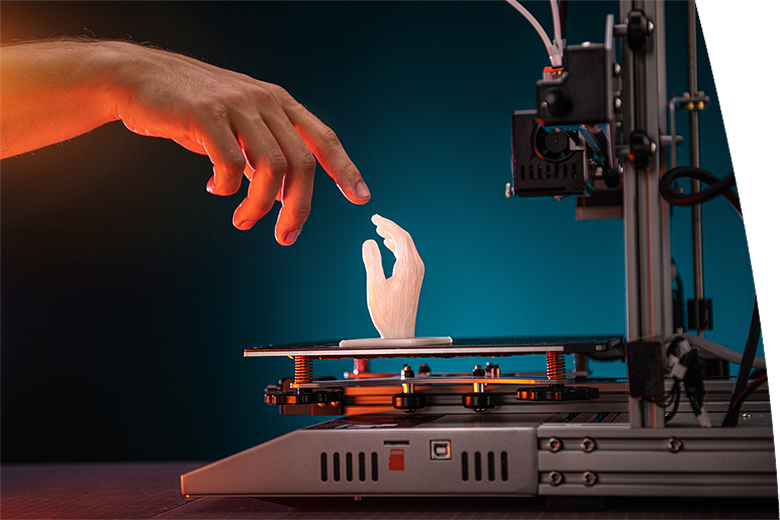

3D printing

One of the most significant technological innovations in the field of production is 3D printing. In the industrial sector, it enables faster prototyping and more efficient production. Therefore, in the years to come, the improvement of materials and the acceleration of printing are expected.

Artificial intelligence

It is no longer just a tool for data collection and analysis but it is becoming a creative partner. In the creation process, it is able to review thousands of designs within a few hours for the designer. In this way, products can be optimized in order to be lighter, more firm, more personalized and, last but not least, also more environmentally friendly.

Cobot

Have you heard about the term cobot? It means a collaborative robot that is made to work safely in close proximity to people. Cobots are expected to be able to collaborate with humans to an even bigger extent, thus increasing productivity and safety in workplaces.

VR and AR

Virtual and augmented reality are able to visualize for designers and engineers their designs in real time. In this way, the functionality of the product can be verified prior to production which unambiguously saves time, money and nature.

Sustainable materials

The world is moving towards increasing sustainability. This is also reflected in materials that are recyclable or biodegradable. Moreover, every production also brings waste in addition to the desired product, thus the phrase circular economy will become used more and more often. We will be able to achieve climate neutrality by producing less waste.

Smart factories

Smart factories can link a network of machines, communication mechanisms but also artificial intelligence and thus create a single digital ecosystem. Such a production can learn from its experiences and even predict trends and so it will become the factory of the future.

The year 2025 will be about the successful and efficient integration of all technological innovations so that you make use of the best of both human and robotic potential and thus stay one step ahead of the competition.